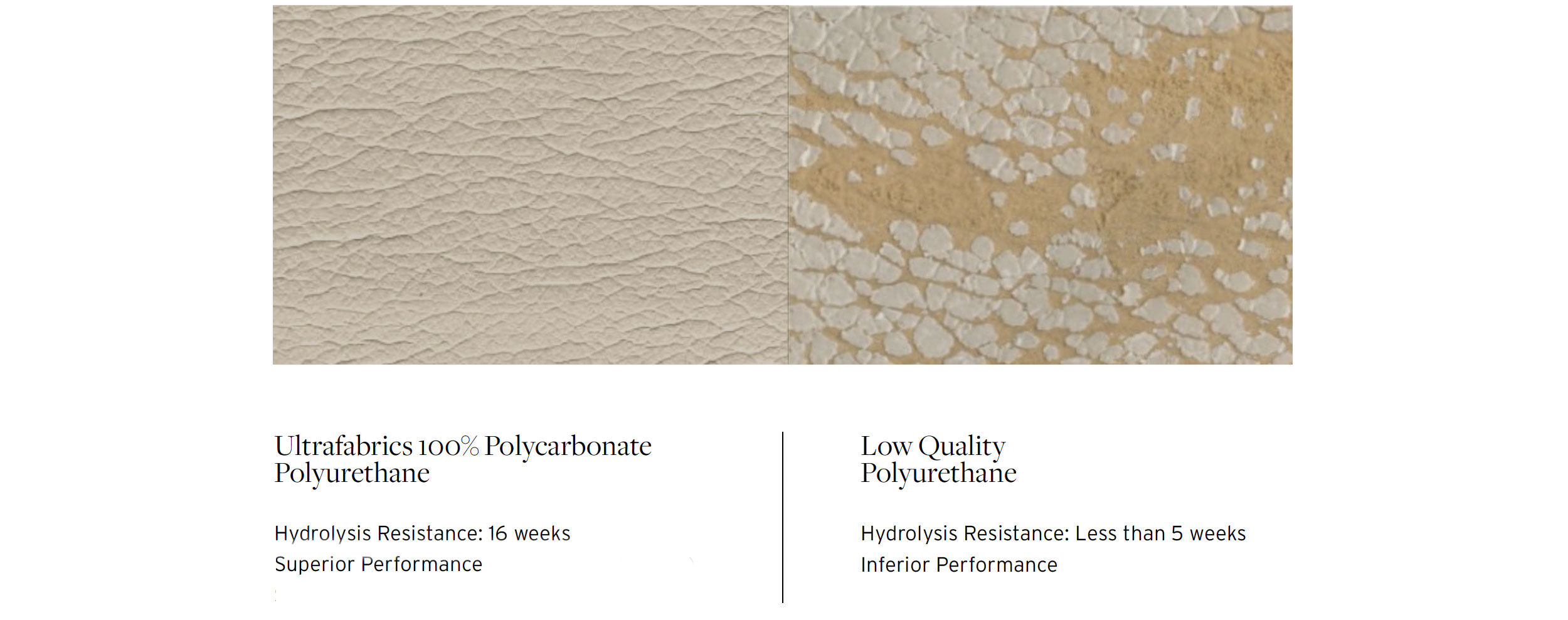

Polyurethane can be affected by heat and moisture, which can cause it to crack, peel, or degrade over time. The material’s ability to withstand those effects is proven through hydrolysis testing. Hydrolysis is a chemical reaction in which a molecule of water breaks chemical bonds. Hydrolysis testing is then used to determine the resistance of a material to chemical breakdown or decomposition due to exposure to water or moisture. This validates polyurethane’s performance and is what you should refer to when seeking the most durable option.

There are two tests commonly used to rate hydrolysis for polyurethane coated synthetic leathers. Ultrafabrics tests to both while most competitive products only test to the passive method.

ISO 1419 ("Tropical" Test, Method C. Also known as “Jungle” Test) — Accelerated-ageing tests

• Sample is placed in a testing chamber at 158° Fahrenheit and at 95% humidity.

• After a pre-determined number of weeks, or until failure, the sample is visually compared to an untested control sample, checking for any signs of degradation, discoloration, or damage.

• A specimen passes if no perceivable change has occurred.

The Association for Contract Textiles (ACT) performance guidelines for coated textiles calls for 5 weeks to deem it a durable material.

ASTM D3690 Standard Performance Specification for Upholstery Fabrics — Indoor (Section 6.11, Hydrolytic Stability)

• A visually inspected sample is placed in a testing chamber at 158° Fahrenheit and at 95% humidity. And physical properties tests are done on an un-exposed control sample.

• After a period in the testing chamber, which can be as low as 15 days or up to UF's remarkable 16 weeks, the sample is visually compared to a control and subject to tests to evaluate the physical properties of adhesion, surface abrasion and resistance to flexing.

• The material only passes if it clears the visual comparison and meets the minimum requirements on all physical tests, with no degradation after the test.

While both expose the tested material to similar hydrolysis conditions, the ISO method could be considered a "passive" test, limited only to an appearance evaluation; while the ASTM method is considered an "active" test since the sample materials undergoes stringent performance evaluation of possible changes before and after being in the chamber.

Ultrafabrics tests both methods, while some competitor products are only tested to the passive method.

Note: There is no direct correlation of testing weeks to years of service in the field. As with any textile, multiple factors including environment, usage, abuse, and application type can contribute to longevity.

The recommended industry minimum (ACT) for hydrolysis resistance is 5 weeks for the ISO Method to be suitable for commercial applications. Thanks to our superior polycarbonate based polyurethane resins, the majority of Ultrafabrics materials test to 16 weeks, head and shoulders above the industry standard.

Exceptions:

Uf Select achieves 10 weeks

Download the Hydrolysis sell sheet

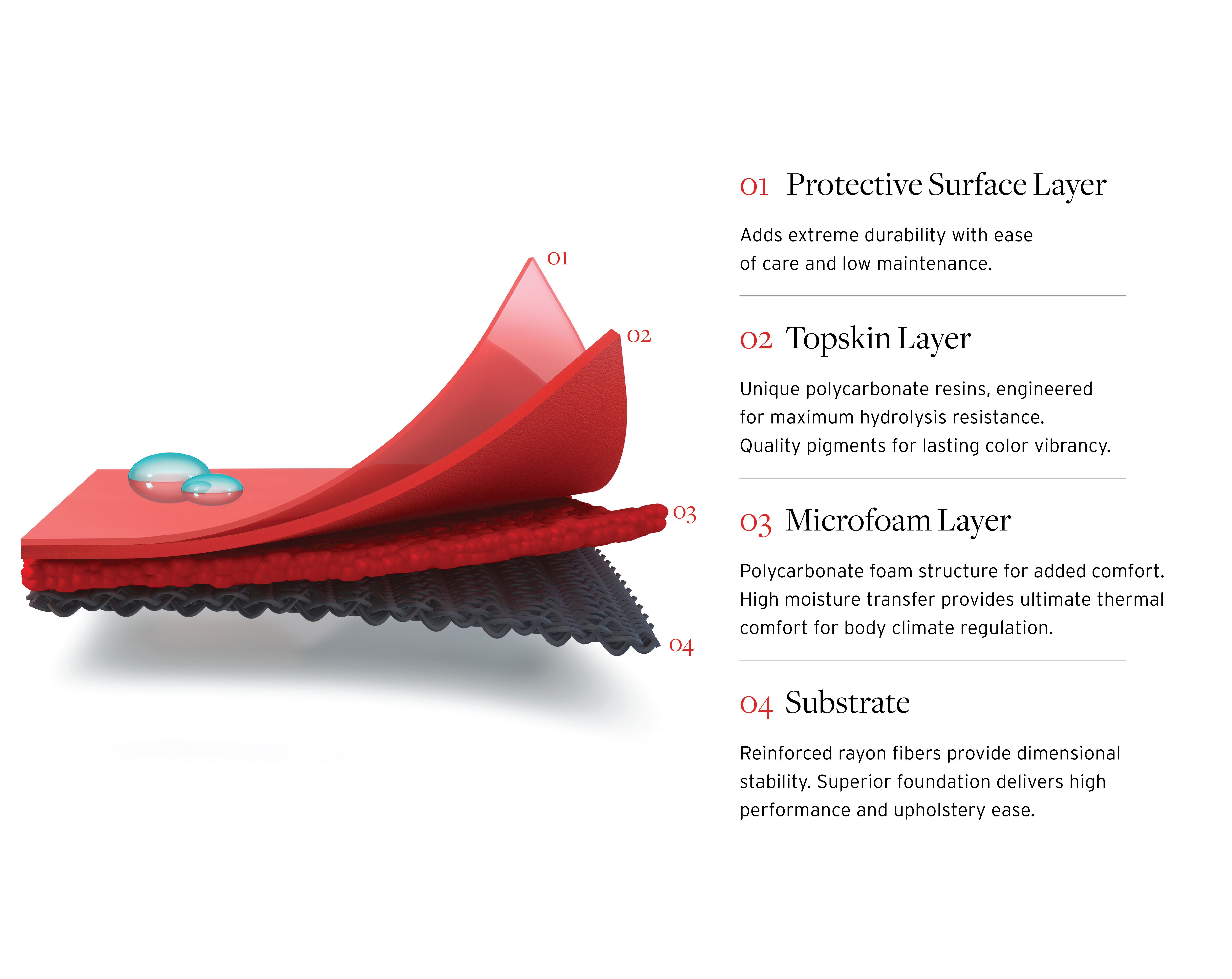

Continually perfected, Takumi is the only process able to achieve the premium quality of Ultrafabrics. Our dedication to perfection and consistency delivers an experience that changes the definition and expectations for performance fabrics.

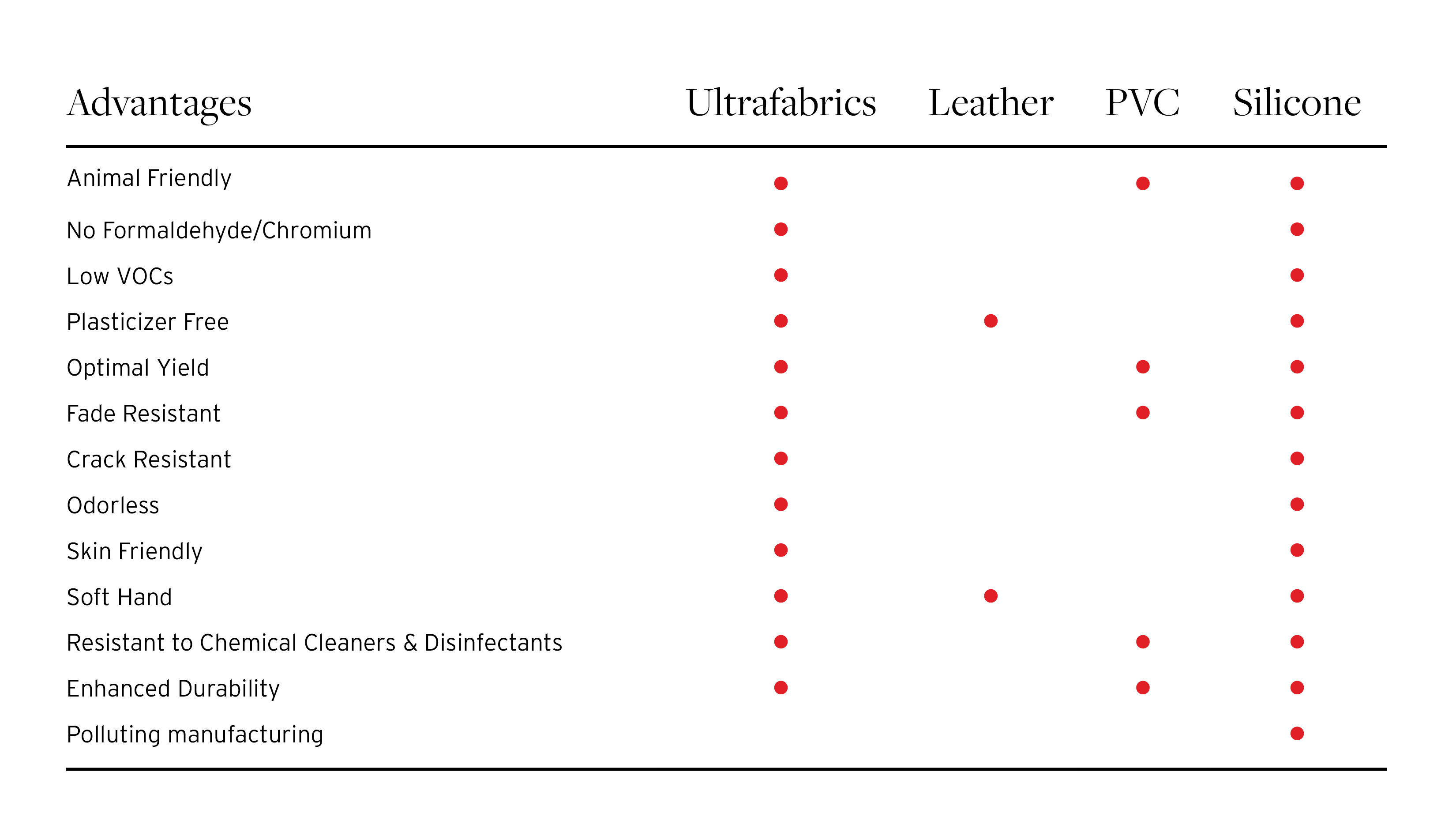

We are proud to be an enduring alternative to leather, PVC, and silicone, supported by attributes like cleanability, comfort, softness, and environmental responsibility. Our premium construction also includes renewable, recyclable, and/or biobased content.

Ultrafabrics offers materials that emulate the look and feel of leather, but with enhanced performance, greater yields, and without the environmentally harmful tanning process.

Ultrafabrics materials do not contain harmful plasticizers contained in vinyl/PVC, nor involves the energy-intensive processes and pollution found in silicone production.