Material innovation has never been more important. For Ultrafabrics, sustainability isn’t an add-on, confined to a separate, isolated product line. In order to be truly responsible, sustainability is infused and crafted into every material, with no impact on the fabric’s function, performance, or beauty. Not only do we consider the inputs of our products from a sustainability perspective, but we’re also committed to exceptional product quality and durability to support the principles of circular economy.

View the full list of certifications and initiatives our materials meet here

For greater detail on what we are doing, see our 2025 Sustainability Report.

- Designed for LongevityOur propriety process, Takumi™ Technology, involves applying the principles of craftsmanship to maximize the performance of each layer of our fabrics. In this way, we make the most effective use of resources already extracted from the earth to produce durable and desirable materials that exceed our customers’ expectations.

- Product Health & Safety

We’re delivering safer materials for our producers and clients alike. Green chemistry is a key focus at Ultrafabrics to ensure we’re managing and mitigating possible environmental and health impacts and supporting a healthy future for the textiles industry.

As part of our commitment to safer chemistry:

- As of last year, all Ultrafabrics products stored and sold in the US are PFAS-free. By 2027, this commitment will extend globally, with all products sold worldwide being PFAS-free as well.

- All Ultrafabrics branded materials have low VOCs and are assessed to pass SCS Indoor Advantage Gold, the highest level of indoor air quality performance for furniture.

- We assess Ultrafabrics products to semi-annual REACH updates to ensure they meet and/or exceed the criteria.

- We have reviewed the Living Building Challenge Red List, and Ultrafabrics products do not contain any Red List chemicals, with the exceptions of our outdoor products (Brisa Frontier, Brisa Forecast, Coast, Pumice, and Summit).

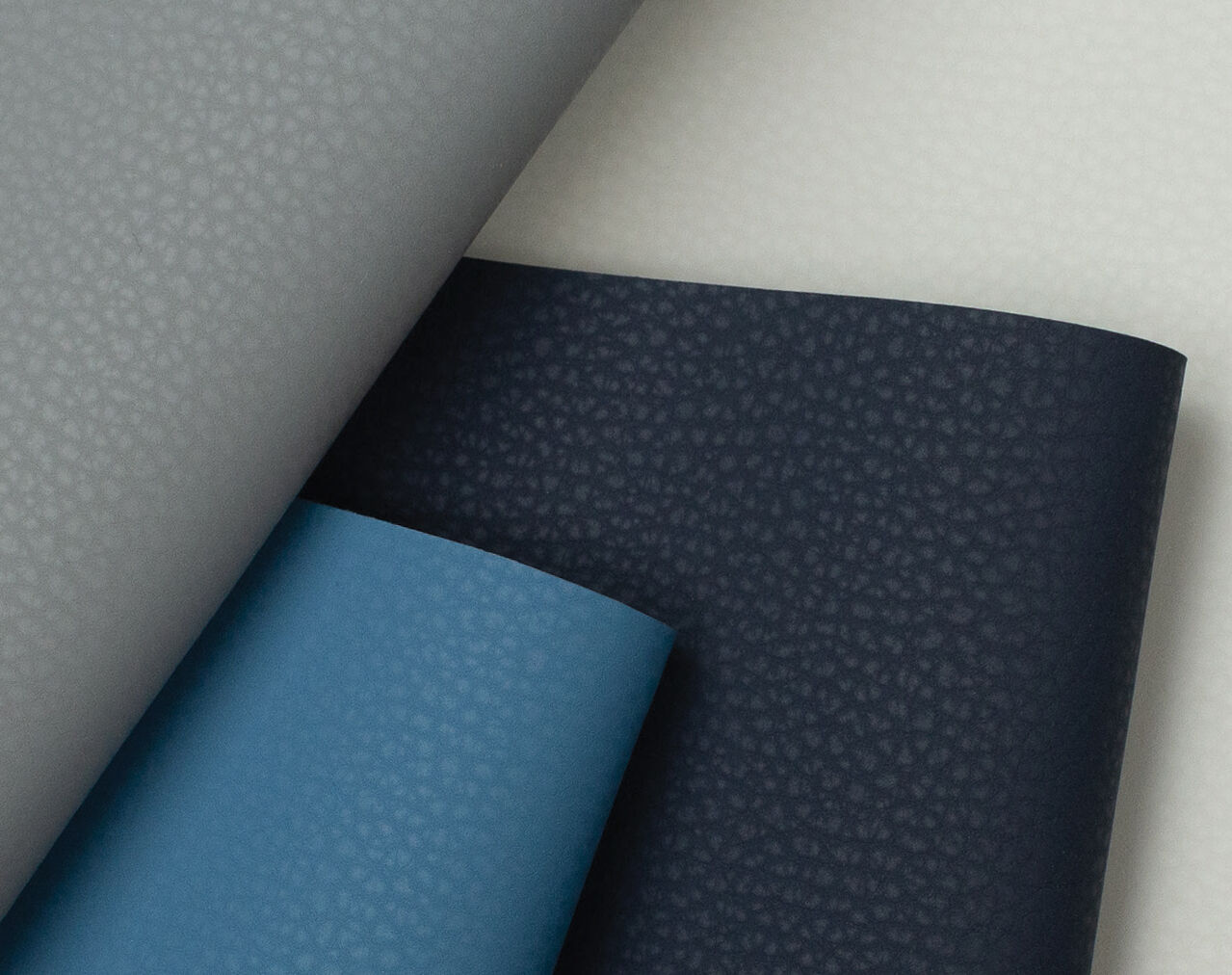

- Material Innovation

As we shift away from virgin synthetic and finite resources, it is essential that the replacements are scalable, plentiful, and derived from rapidly renewable or recycled sources. These new materials must also withstand the performance requirements of diverse applications.

Our initial investment in these materials began about a decade ago when we became the first and only polyurethane branded partner to utilize TENCEL™ Modal in our collections.

We then introduced our first biobased collection in 2019, Volar Bio. Since then, we’ve been working to increase our use of environmentally preferred materials in our backings and resins to improve the sustainability of our materials portfolio.We reached our sustainable material goal a year ahead of our 2025 target, reinforcing our commitment to innovation. All Ultrafabrics-branded products for furniture, healthcare, RV, marine, aviation, and accessories contain at least 50% environmentally preferred materials. By 2030, our Uf Select portfolio and transportation-grade materials will also meet the same standard.